Design

In our experience, very few graphic designers are expert paper engineers. So we recommend you work with us to get the foundation right before you brief your designer to develop pack graphics. If you want your designer to have conceptual input before we develop prototypes, that’s easy. We’re great collaborators.

Prototypes

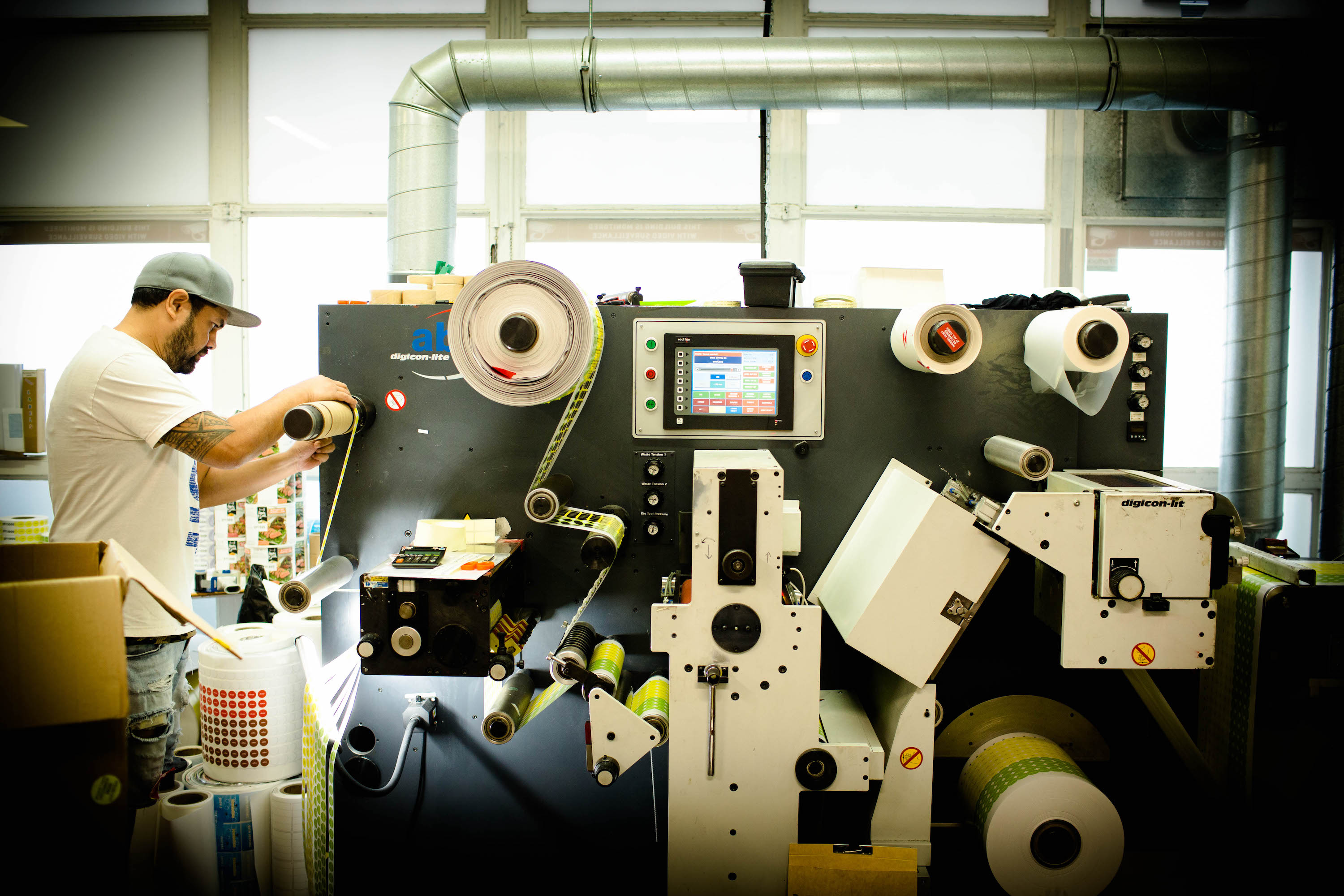

To eliminate costly mistakes before they occur, SCG includes a mocked-up prototype in our pack print process. As far as we know, we’re the only NZ packaging printer to make printing of an accurate prototype standard procedure. One-off prototypes are printed digitally and laser cut using the correct stock. If problems are discovered, adjustments can be made before the digital or offset print run.

Multiple SKUs

Combine multiple SKUs on a single run, ordering exactly the quantities you need. Variable data from an Excel spreadsheet can allow you to print with consecutive numbers, competition codes, traceability barcodes and personalised messages. You can even change out images if you want to.

Colour & Embellishments

If your labels need to match other packaging elements, such as a box or bag, our colour management processes ensure your brand colours stay true for every piece. Specialty coatings can be added for ‘higher perceived value’, such as matte soft touch or super high gloss. We use a Color-Logic system that enables us to digitally print onto metallic substrates, producing striking images and colours by masking with white ink.

Here’s a quick summary of our labels & packaging capabilities:

- Digital printing with variable data for labels, prototypes, cartons and flexible film

- Offset printing for folding cartons, cardboard sleeves and high-volume labels

- Continuous image printed pallet wrap rolls 30mm wide

- Shippers that double as point of sale displays

- Carton outers to snugly fit bundles products

- Stand-up pouches and sachets

- Shrink Sleeves

- Hang-sell cards

- Gift Boxes